Stainless Steel Filter Presses - German Manufactured

Applications:

- Pharmaceutical

- Blood Plasma

- Protein Cell Harvest

- Clarification of Vaccines

- Clarification of Antibiotics

- Chemistry – Chemicals

- Food and Beverage

- Beer and Wine

- Juice, Cider, Vinegar

- Cosmetics

- Waxes

Features:

- Stainless Steel Construction

- Food Grade

- Steam Jacketed Filter Plate Option with Heatable Plates and Frames

- Explosion Proof Models

- High Quality Precision German Construction

- Manual and Automated Models

- Membrane or Recessed Chamber Models

- Sterile Filtration

- Filter Sheets or Plates and Frames

- Plate version can be with or without Gaskets

- Precoat Filter (Kieselguhr Filtration)

- Works as a Closed System

The following brochures are available for download:

Thanks to our diverse know-how in many different areas, we are able to supply a customized, mature and reliable system that meets every special demand. After all, we are never satisfied with our products until the solution for our customers is clear.

As the technology leader in the area of solid/liquid separation, we and our engineers constantly seek to develop new technologies and to put our proven technologies to use in new areas of application and new markets. In fact, we were able to present several new technological innovations in recent years:

• A closed depth filtration system that is mainly used in the pharmaceutical industry to fractionate blood plasma

• Fully automatic cross flow systems for the filtration of wine and juices for large wineries and cooperatives

• A heatable chamber filter press that combines the processes filtration, washing of the filter cake, and drying in a single device. This method is used to produce white pigments, for example Quality and first-class workmanship require modern management systems. For this reason, we introduced a quality management system back in 1999. Since then, we have been audited for the effectiveness and observance of our standards in our QM system on an annual basis.

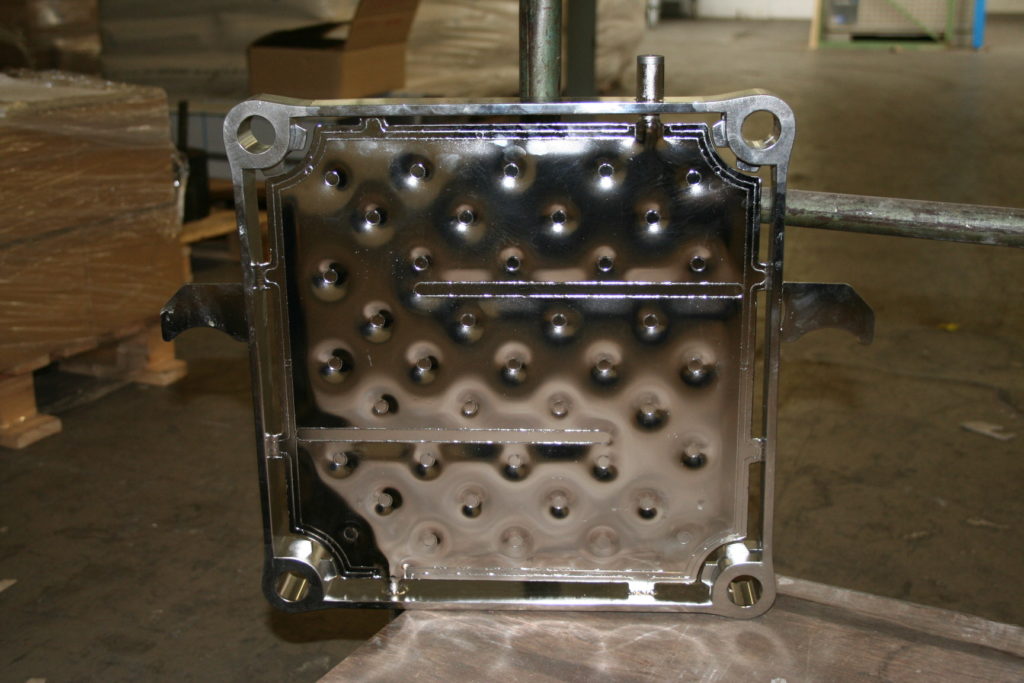

THE PLATE AND FRAME FILTER PRESS SFoDPC OR SFoDEC CLEAN SYSTEM

Both the multilayer filter SF oDPC and the SF oDEC CLEAN

SYSTEM are designed to meet the unique demands of the

pharmaceutical industry. The design was developed specifically

to meet the high demands for hygiene and purity. These

can be used for a broad spectrum of applications, including

fractionating of blood plasma, harvesting of proteins, and clarifying

filtration of vaccines and antibiotics. The filter plates are

sealed by surrounding O-ring seals on the filter plates and

the interior filter layers. This creates a 100% seal without any

leakages. The product thus does not come into contact with

its surroundings. The possibility of performing CIP cleaning

and SIP sterilization is also unique. The system is available

with filter plates made of stainless steel or polypropylene.

THE PLATE AND FRAME FILTER PRESS SF oD

The multilayer filter SF oD (closed hood optional) is

designed especially to meet even the highest demands

of the chemical industry. This design was developed

to meet the special demands that pertain to aggressive

media and high temperatures. It can be used for a

broad spectrum of applications in solid-liquid separation,

including filtration of surfactants, oils and catalysts,

etc.

Sealing of the product channels in the filter plates

takes place via the filter layer. The plate package can

be closed by using a hood to ensure the highest safety

even with extreme temperatures and substances that

pose a risk of explosion. It is also possible to equip the

filter frames with heating elements to keep the temperature

constant.

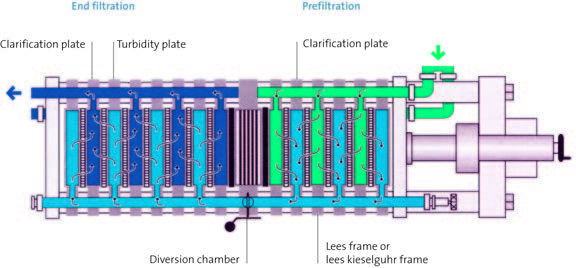

PLATE AND FRAME FILTER PRESS SF B

The multilayer filter SF B is designed especially to meet the

needs of the beverage and food industry and can be used for

a broad spectrum of filtration tasks, including filtration of wine

and beer. Through the four-eye principle of the filter plate, this

classic multilayer filter achieves ideal flow and thus ensures the

efficient use of the filter sheets and outstanding

filtration results. A diversion chamber can be used to perform

multi-step filtration.

This system can be used very flexibly thanks to the wide range of

filter media that offer various separating efficiencies. It is available

in different versions and various types of stainless steels.

FILTER PRESSES

The chamber filter press KFP or membrane filter press MFP can be used to filtrate and drain liquids that contain solids. Particularly

good results are achieved with membrane plates that are capable of exerting additional internal pressure on the filter

cake by generating compressed air. This is also of benefit in washing the cake.

The chamber or membrane filter press is generally used in

the beverage and food industry to filter juice and wine gently.

It is available in the following versions:

• Equipped with membrane or chamber plates

• As a Clean System for a hermetically sealed and

aseptic filter

• Together with traditional drape over cloths

Multi Stage Filtration

EVERYTHING FLOWS

Thanks to our many years of experience in the area of solid-liquid separation and innovative

ideas as a technology leader, we are capable of finding customised filtration solutions in a

quality that suits the respective application.

BEVERAGES/FOODS

The quality of the product is our most important priority when it comes to filtration of beverages and foods. Taste and gentle processing, and brilliance and clarity are closely interrelated. Decades of experience and in-depth expertise make us a highly skilled partner in this area.

Wine

The Strassburger chamber filter press Clean System that has membrane plates is a universal device for every expansion stage with which the must and wine are filtered. Here, the filtration is so gentle that the aroma and the character of the wine are not affected. Many well-known wineries and sparkling wine producers from premium

quality growing regions rely on our technology. With the Strassburger Micro-Cross system, complete sterilization of the filtrate is achieved with only one filtration. No

other filter aids are needed. This technique can thus be considered a cost-effective and environmentally-friendly alternative to conventional filtration techniques.

Beer

For our customers who make beer, we offer kieselguhr filtration that uses plate and frame filter presses, as well as sterile filtration as a sheet filter or a combination of the two.

Vinegar

With filtration of vinegar, the sterility of the process and thus the shelf-life of the product are extremely important. Here, we have achieved the best results and references with our Strassburger MicroCross system.

CHEMICALS

Aggressive media and high temperatures determine the standards for manufacturing and the workmanship of filtration systems. Our filter systems are used to produce surfactants and technical oils in the fine chemical industry. The sheet filter that has no gaskets is a filtration system that we developed to meet the special demands of the chemical industry. The design is oriented toward meeting the high demands placed on temperature stability, but also toward specially selected materials due to aggressive media.

PHARMACEUTICALS

The highest demands for purity, a design that suits GMP, high surface quality and flexibility in terms of filtration capacity determine the standards in workmanship and manufacturing of filtration systems for the pharmaceutical and biopharmaceutical industries. Micro-, ultra- and nanofiltration systems are used to filtrate protein solutions. Sheet filters without gaskets are used to fractionate blood plasma, to concentrate and fractionate enzymes, for sterile filtration of vaccines and serums, and for diafiltration.

Strassburger Filter Press

Customized filtration solutions for use by a wide variety of different industries are our

specialty – for over 95 years. Hermann Strassburger founded the company that is named

after him in 1919.

Back then, the main focus was on manufacturing filter apparatuses that were initially used in wine making,

but later also in the fruit juice and vinegar industries. A number of new areas of application

were developed over the years. Today, we are active with our systems in the beverage and food

sector, but also in the chemical and pharmaceutical industries, where the highest standards for

safety and hygiene apply.

We constantly conduct research and develop our products further so that we can offer our

customers the most innovative and appropriate applications. Here, we place particular

importance on economics and ensure that our products function in a cost-effective, profitable,

and environmental-friendly manner.

Our filters are used for the clarification and sterilization of all kinds of liquids.