Slurry Sampling Protocols

8.1 General Comments

Proper sampling of the slurry, filtrate, cake, and wash effluent are important to assure good quality data to size the filter press.

8.2 Slurry

A slurry sample must be taken for every test. If the same sample will be used for screening and filtration tests only a representative sample must be taken.

If a fresh sample is used for any test then a representative sample of each sample used must be taken. Note that a “sample” that is sent in several 5 gal pails is not one sample, each pail may be slightly different, either mix all the pails together to make one homogeneous sample or treat each pail as a separate sample. When conducting onsite testing, one must not assume that the sample has not changed, even the customer says it does not. A sample of each slurry batch used must be taken to verify this. It is common for there to be small variations in the slurry that could be important in understanding the filter press behavior.

A representative sample is one that has been thoroughly mixed; it has the exact sample composition anywhere. Thus, one can take a sample from any point in the sample and be confident that it is the same throughout. The thorough mixing may be difficult for some slurries that are very thick or have very fast settling solids. However, one must strive to always get the most representative sample possible.

The minimum sample size is 500 ml for routine solids and density tests that are always required. If more analytical testing is required for understanding, the test results a larger sample will be required. The analytical requirements for the specific procedures will dictate the minimum sample size that must be taken and coordination with the laboratory is required.

Normally the slurry sample is not treated or stabilized (“preserved”) but some analytical procedures may require a special preserved sample. Coordination with the laboratory is required to insure that a properly preserved sample is taken. When this occurs there will be several samples with different types of preservation and one with no preservation taken.

8.3 Filtrate

There are two basic types of filtrate samples: composite and grab. A composite sample is one that is made from combining all the filtrate from the test and thoroughly mixing and then taking a sample. A grab sample is taken a specific point in time. The difference between the two types is that a composite sample is an average of the filtrate over the entire run while a grab is a sample at a particular point in time. When using a grab sample one normally takes a series of samples at specific time intervals to monitor changes in the filtrate over time.

The basic filtrate test is total suspended solids and it requires an unpreserved 1 liter sample. Again, there may be other analytical tests requiring a larger sample or a properly preserved sample. Coordination with the laboratory is again necessary to insure that the proper samples are taken.

8.4 Cake

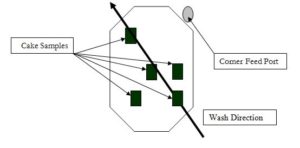

As described earlier, one should take cake samples away for the cake edges and core area of the cake. Also, each cake should be sampled and either a composite cake sample of all the cake in the press or sample of each cake is taken and analyzed separately. Normally the latter is preferred because the cake is not usually truly homogeneous either across the cake or front to back on the filter press.

The normal cake tests are total solids and density. For the pilot presses the preferred sample size for each solids test is about 50 – 100 gm of cake and about 300 gm for the density for 500 gm. This quantity is not always practical and adjusts can be made to accommodate the available cake quantity. The bench test does produce very much cake so the sample sizes are reduced to about 10 gm for the total solids and about 20 – 30 gm for the density.

Additional cake samples may be required for analysis and sufficient cake must be taken for these analyses while coordinating with the laboratory.

When cake washing is done (using a pilot press) more cake samples are required to understand the spatial efficiency of the wash. Several samples throughout the cake are taken and individually analyzed as shown in Figure 7.

8.5 Wash Effluent

The wash effluent samples are normally grab samples taken specific time intervals to monitor the change of a parameter in the cake with time. The analytical requirements will determine the number, size, and preservation of the samples taken at each grab.

Common tests done on the wash effluent are pH and conductivity, both require relatively small sample sizes that are not preserved.

The goal is determine an easily measured parameter such as pH that changes in a similar manner to the constituents being removed during the cake wash. Note that the parameter being monitored in the cake is not always the same as the parameter monitor for wash effluent. The selection of the appropriate parameters are generally made before the testing begins.

Figure 7. Typical Cake Sampling for Washed Cakes