Filter Press History – R & B

Vaillant Group – Remscheid, Germany

Vaillant, one of the largest manufacturers of hot water equipment in Germany, used a neutralization and detoxification plant with static thickening for treating the effluent from the electroplating facilities up to a few years ago. The suspensions produced were concentrated to a water content of 98% and the resulting thin sludges transported by tankers to storage faculties.

After investigating various systems of dewatering, it was decided to employ Rittershaus & Blecher filter presses (R & B Filter Press). The volume of sludge was reduced to 1/15 of the previous figure, and in contrast to the thin sludge previously produced, it was possible to dump the filter cake (moisture content 67%) without risk of contamination ground water. There was also a considerable cost saving due to the smaller volume of material to be transported.

Filter Press History – Hüttenwerke Oberhausen AG, Jacobi Pit

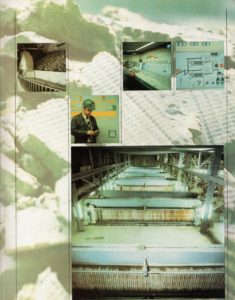

At the Jacobi Pit of the aforementioned concern four (4) chamber filter presses supplied by Rittershaus & Blecher (R&B) with a total filter area of 600m² are installed. They dewater 8 tons of dry matter from flotation effluent per hour; this effluent being produced by concentration at the rate of 300g/liter.

These suspensions, which used to be transported to settling ponds, can be dewatered to a residual water content of some 20% by means of filter presses using a working pressure of 12 to 15 bar-without any filtration aids being needed.

Filter Press History – Lagerdorf-A Cement Plant near Kiel

In 1963, Rittershaus & Blecher (R&B) was asked to conduct a number of tests relating to the dehydration of raw cement slurries.

The customer’s intention was to reduce as far as possible energy consumption and expenditures incurred during the thermal dehydration of the raw material. They wanted this, as well as the ability to produce high-quality cement by means of bigger and more economical kilns. This required an efficient pretreatment involving mechanical dehydration.

To meet the requirements, Rittershaus & Blecher developed filter presses which operated at pressures of up to thirty (30) bars (425psi), produced an output of forty-five (45) tons of filter cake per hour and required only a minimum of operator attention. By means of the Rittershaus & Blecher filter presses the water content of the cement slurry was reduced from 42% to 19%. There remained only a minor proportion of 19% residual water to be dehydrated thermally, which meant considerable savings in energy and costs.

In addition, the quality of the cement produced was greatly improved since the soluble alkalis could be removed with the filtrate.

At present sixteen (16) R&B filter presses Type A4 1500 S are installed at the Lagerdorf Plant with a filter area of 400m² (4,300 sq. ft.) each.