Filter Press Sizing Calculations

The attached graphs and data sheets are for your use in estimating filter press sizing and chemical dosing requirements. All calculations used in preparing this material are based on the following:

Cake dry solids: 30% by weight

Cake density: 75#/ft³

Ferric chloride dose: 5% by weight

Ferric chloride concentration: 40%

Lime dose: 25% by weight

We expect that the typical process will have a slurry with greater than 3% dry solids that will be processed eight (8) hours per day and that the customer can expect to run approximately three (3) filtration cycles in this eight (8) hour period. When the slurry dry solids content is less than 3% by weight, the cycle time will be longer and therefore these applications should be directed to us for special considerations.

When estimating the filter press sizing requirements for a customer, the following steps must be followed:

1) Determine the customer’s processing requirements

-Slurry type

-Slurry % D.S. by weight

-Gallons of slurry to be processed per day

-Allowed processing time per day

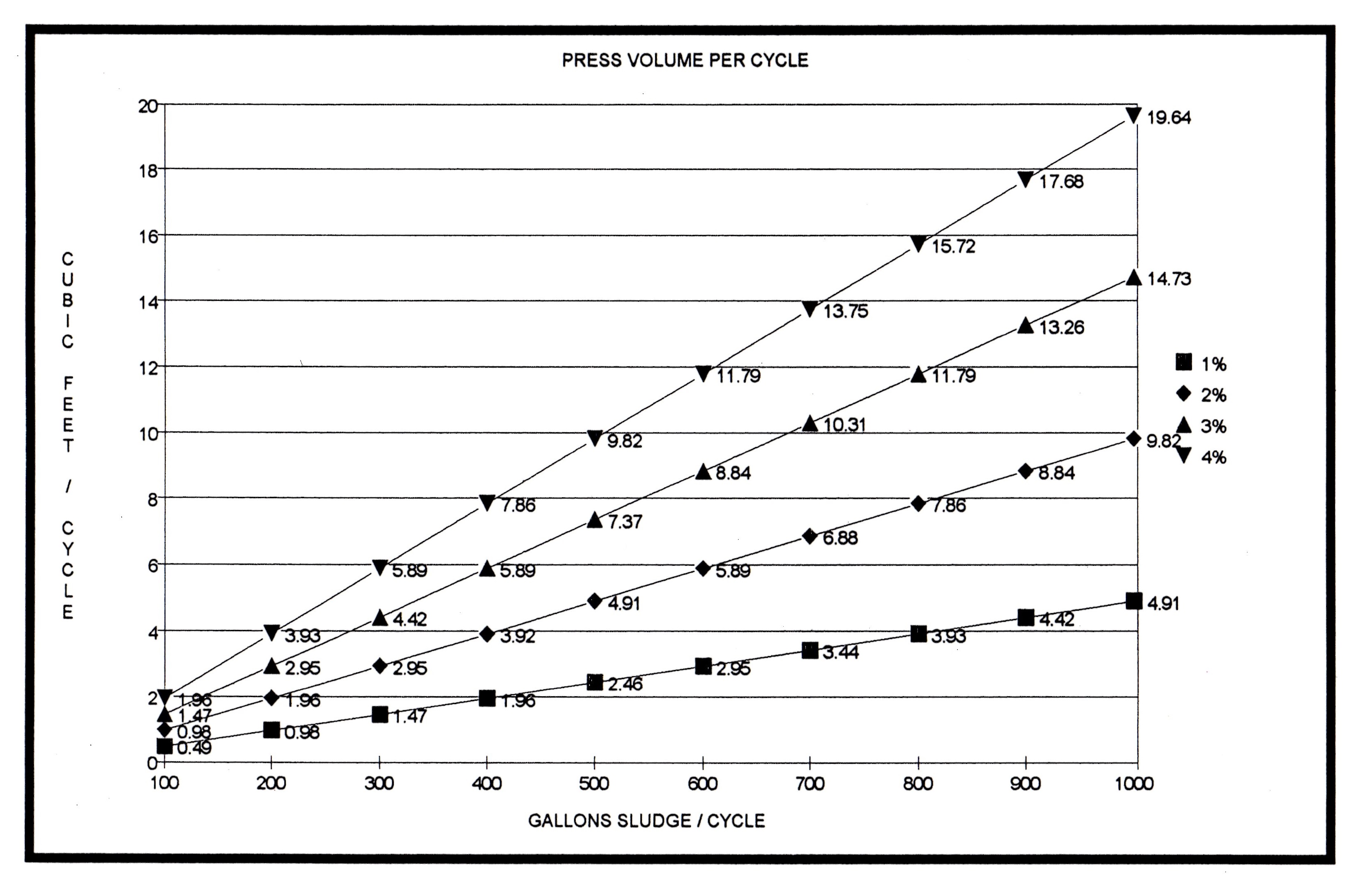

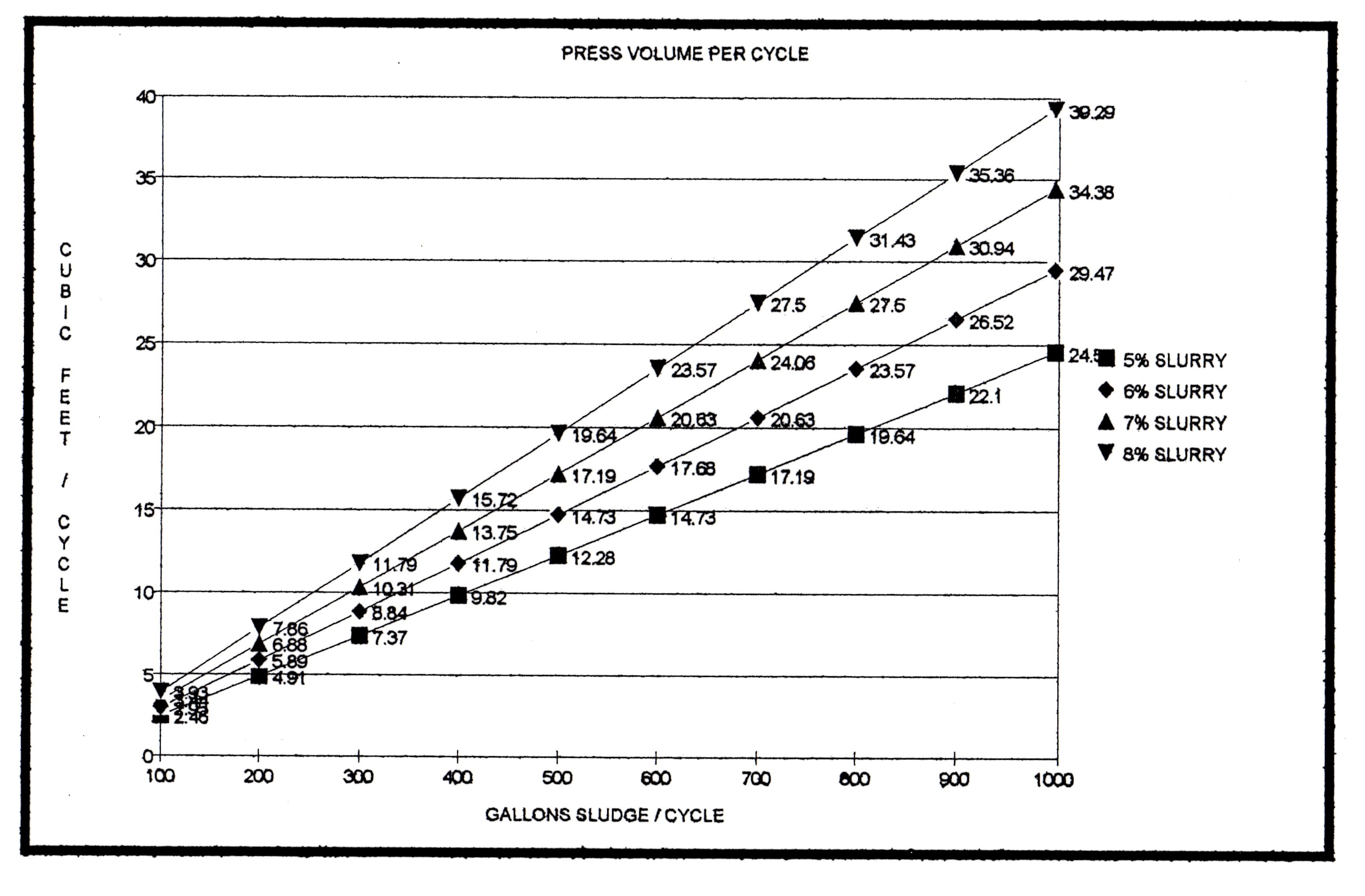

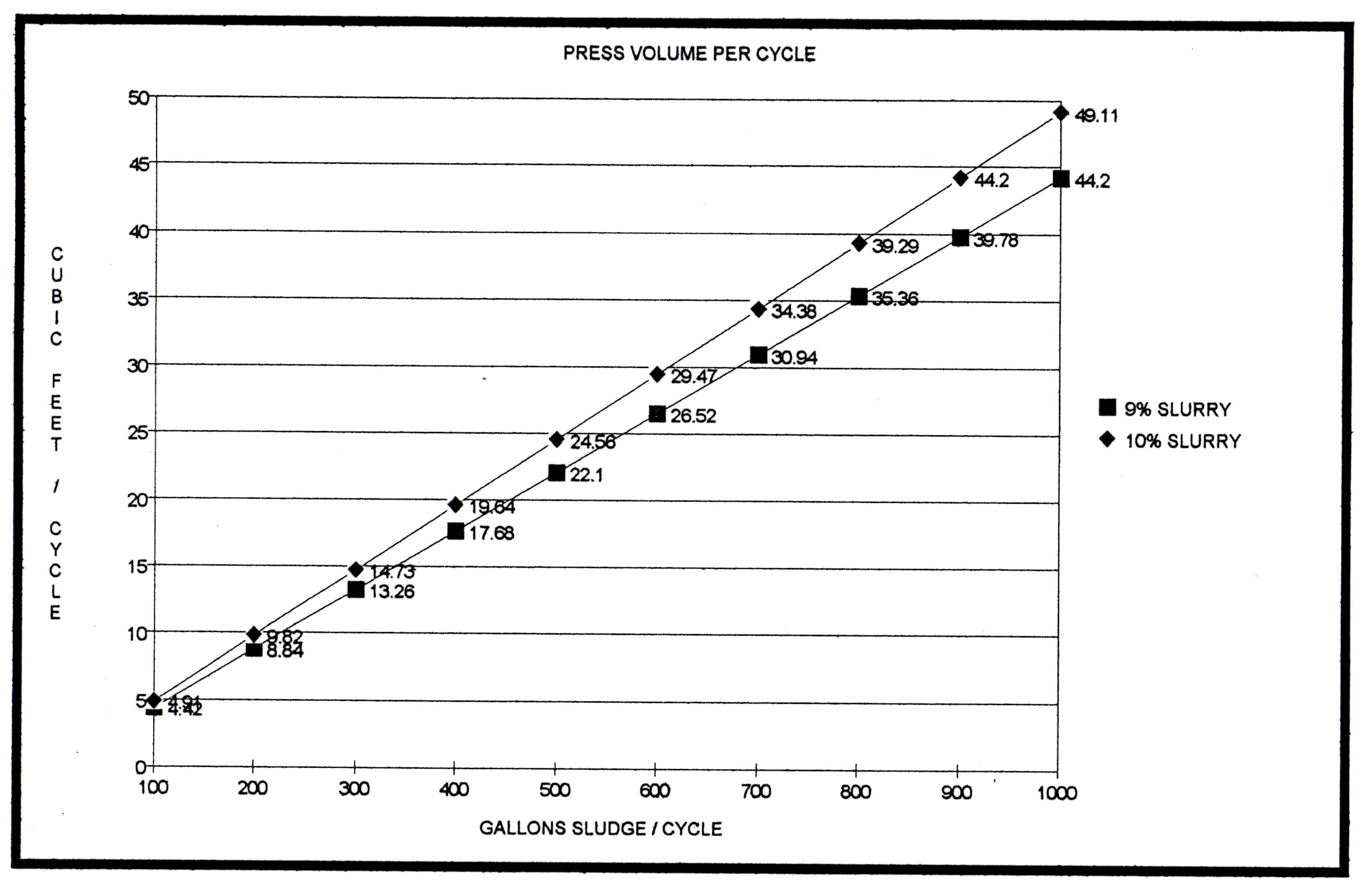

2) Select the appropriate “press volume per cycle” graph that corresponds with the customer’s slurry % dry solids content.

3) Divide the gallons of slurry per day by 3 to determine gallons of slurry per cycle.

4) Find the gallons of slurry per cycle on the graph that you selected in step #2 and follow this value vertically until you reach the line that shows the appropriate slurry % dry solids.

5) Follow this point to the left side of the graph to determine the required press volume per cycle. This is the press volume in cubic feet.

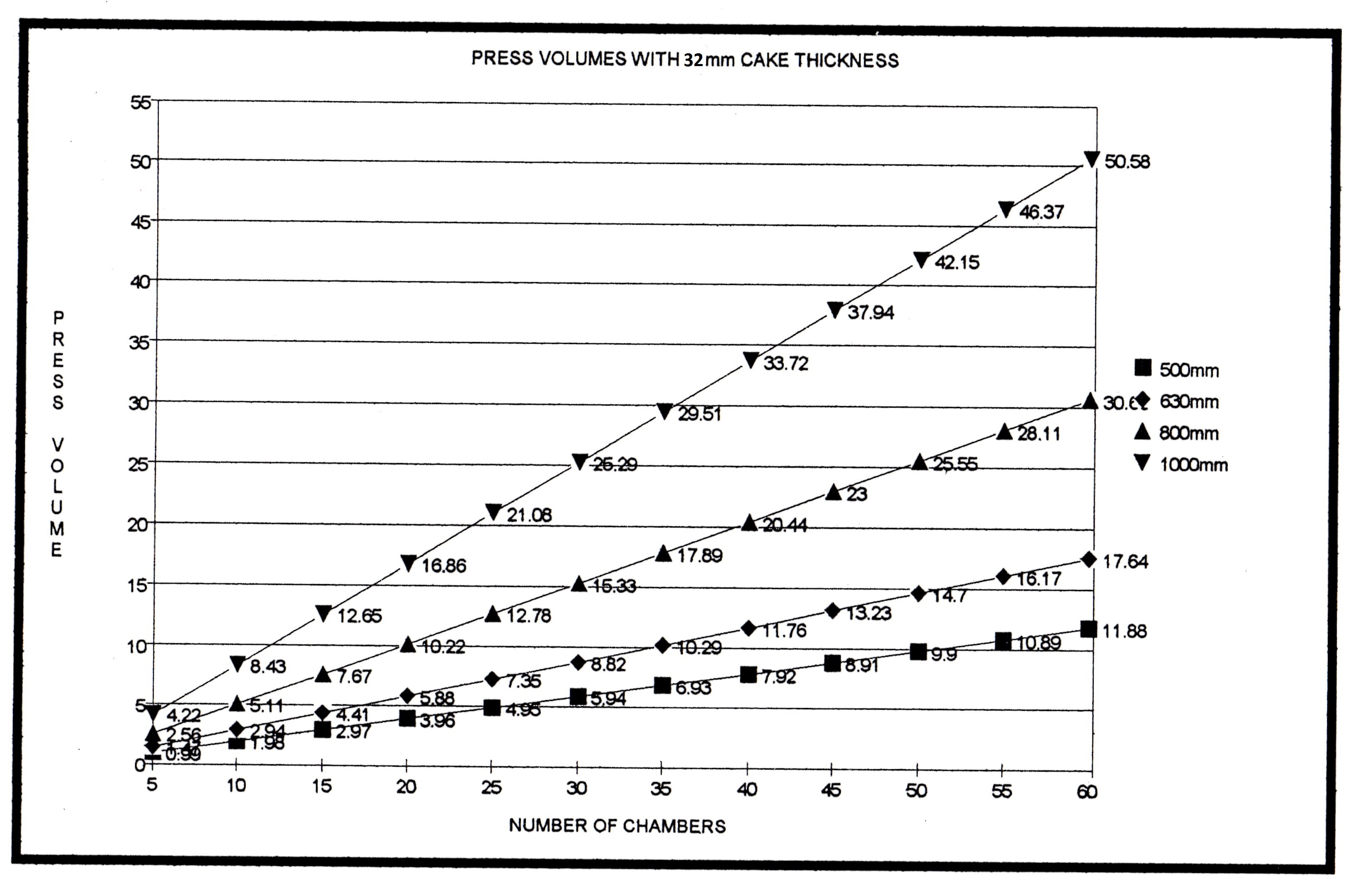

6) Find the graph labeled “press volumes with 32mm cake” (25mm cake for slurries less than 3% solids).

7) Using the press volume that was determined in step #5, find the different press sizes available for the required volume.

Note: In most cases, you will find more than 1 option available. Please consult with us to determine which option is the most cost effective.

When estimating the lime and ferric chloride conditioning required to process the slurry, the following steps should be followed:

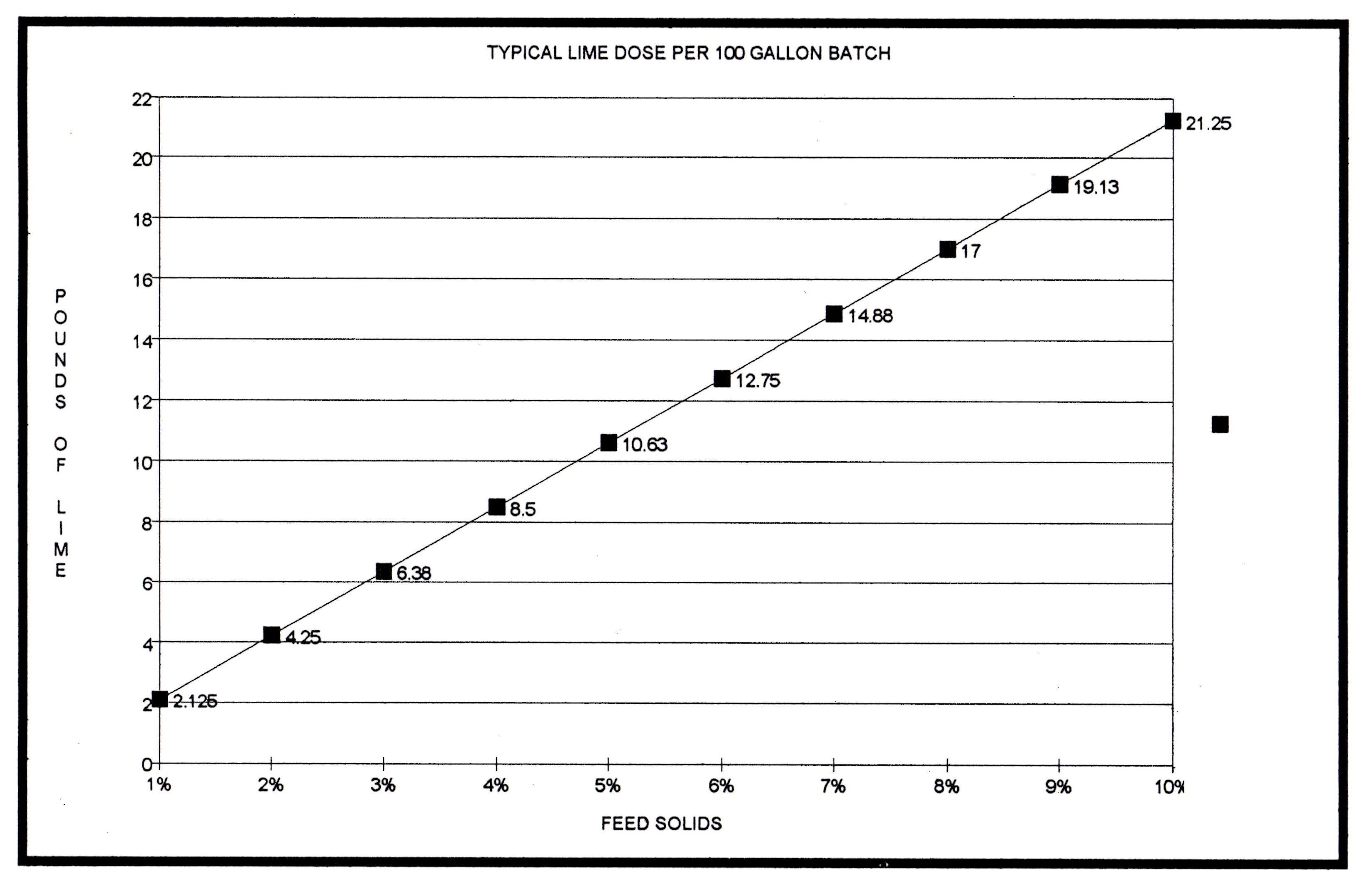

8) Find the graph titled “typical lime dose per 100 gallon batch”.

9) Find the customer’s slurry % D.S. by weight along the bottom of the graph and follow this vertically to find the dry lime dose required per 100 gallon batch.

10) Multiply the value found in step #9 such that the lime dose will be scaled up to meet the customer’s batch size.

Note: We have provided typical lime dose requirements as if dry lime were being added to the slurry. In most cases, the lime will be mixed with water to provide a lime slurry that can be added to the customer’s slurry. The lime requirements have been provided in this manner with hopes that it will be easier for the customer to estimate his chemical costs.

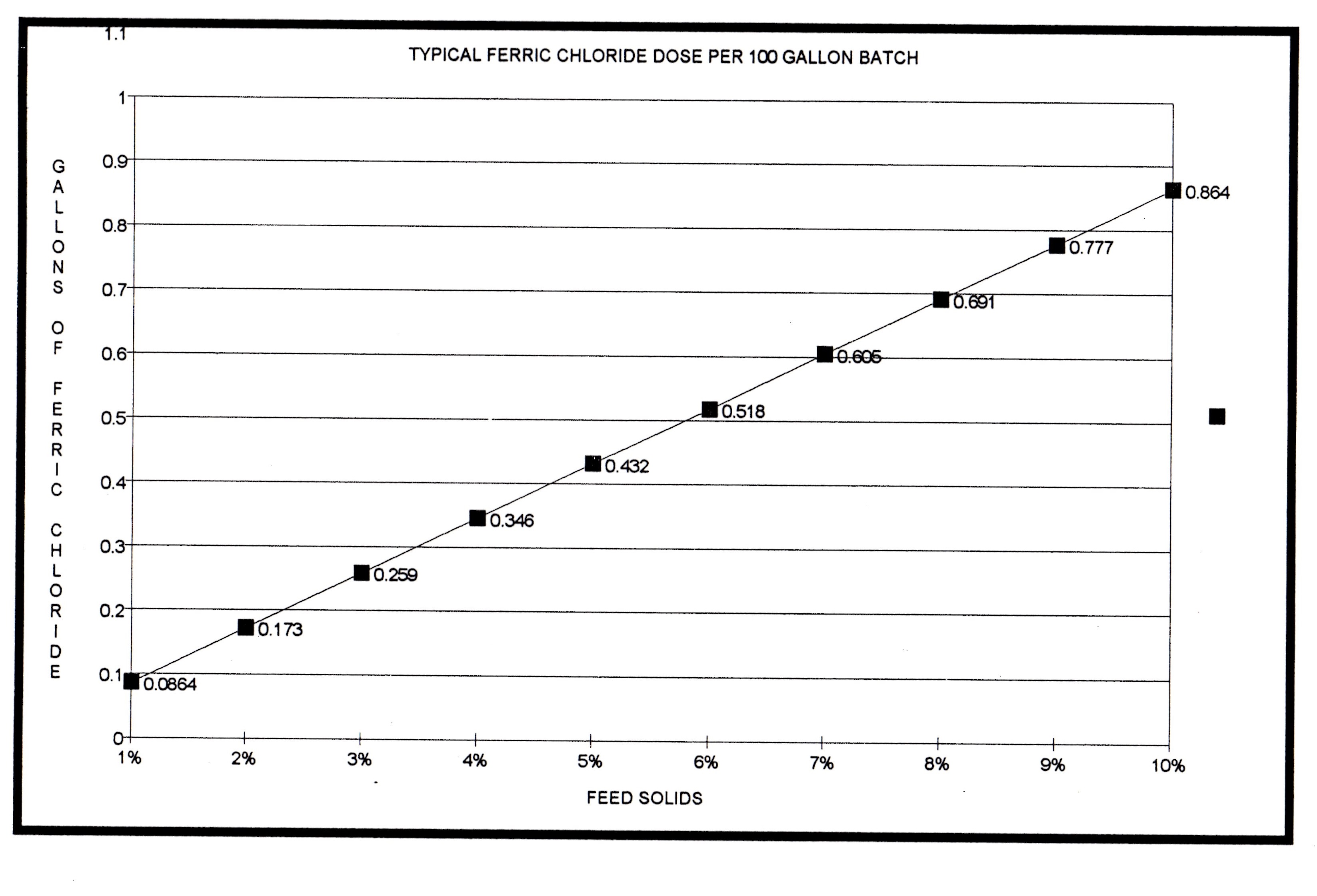

11) Find the graph titled “typical ferric chloride dose per 100 gallon batch”.

12) Find the customer’s slurry % D.S. by weight along the bottom of the graph and follow this vertically to find the gallons of ferric chloride required per 100 gallon batch.

13) Multiply the value found in step #9 such that the ferric chloride dose will be scaled up to meet the customer’s batch size.

Filter Press Sizing Example

We have been talking with a customer and he has given us the following information:

-Slurry type: Wastewater

-Slurry % dry solids by weight: 8%

-Gallons of slurry to be processed per day: 1800 gallons

-Allowed processing time per day: 8 hrs.

With this information, we can estimate the filter press volume and chemical conditioning requirements.

1800 gallons/day ÷ 3 cycles/day = 600 gallons/cycle

Now we can go to our “press volume per cycle” graph to determine the press volume.

We now know that our customer will need a press with a capacity of approximately 24 cubic feet. With this information, we can now find out which presses are available with a 24 cubic feet capacity by referring to the graph titled “press volumes with 32mm cake thickness”.

We now see that there are two (2) presses available that will meet our customer’s needs:

- 800mm filter press with approximately 48 chambers

- 1000mm filter press with approximately 29 chambers

Either option may be suitable but we must also consider plate shifting time/manpower required if the filter press is not equipped with an automatic plate shifter and any space limitations that the customer may have.

Chemical Conditioning Example

We know that the customer’s slurry % D.S. by weight is approximately 8%. With this, we can use the graph titled “typical lime dose per 100 gallon batch” to estimate how much dry lime will be required to process one (1) batch.

We can see that approximately 17 pounds of lime are required per 100 gallons of 8% slurry and can calculate the following:

17 lbs. lime/100 gal batch x 6 (for 600 gal batch) = 102 lbs. of lime

Now we know that our customer will use approximately 102 pounds of lime for each filtration cycle.

We can also estimate the ferric chloride required in order to process one (1) batch just like we did for the lime.

.68 gal ferric/100 gal batch x 6 (for 600 gal batch) = 4.08 gal

.68 gal ferric/100 gal batch x 6 (for 600 gal batch) = 4.08 gal

Now we also know that our customer will use approximately 4 gallons of ferric chloride for each filtration cycle.